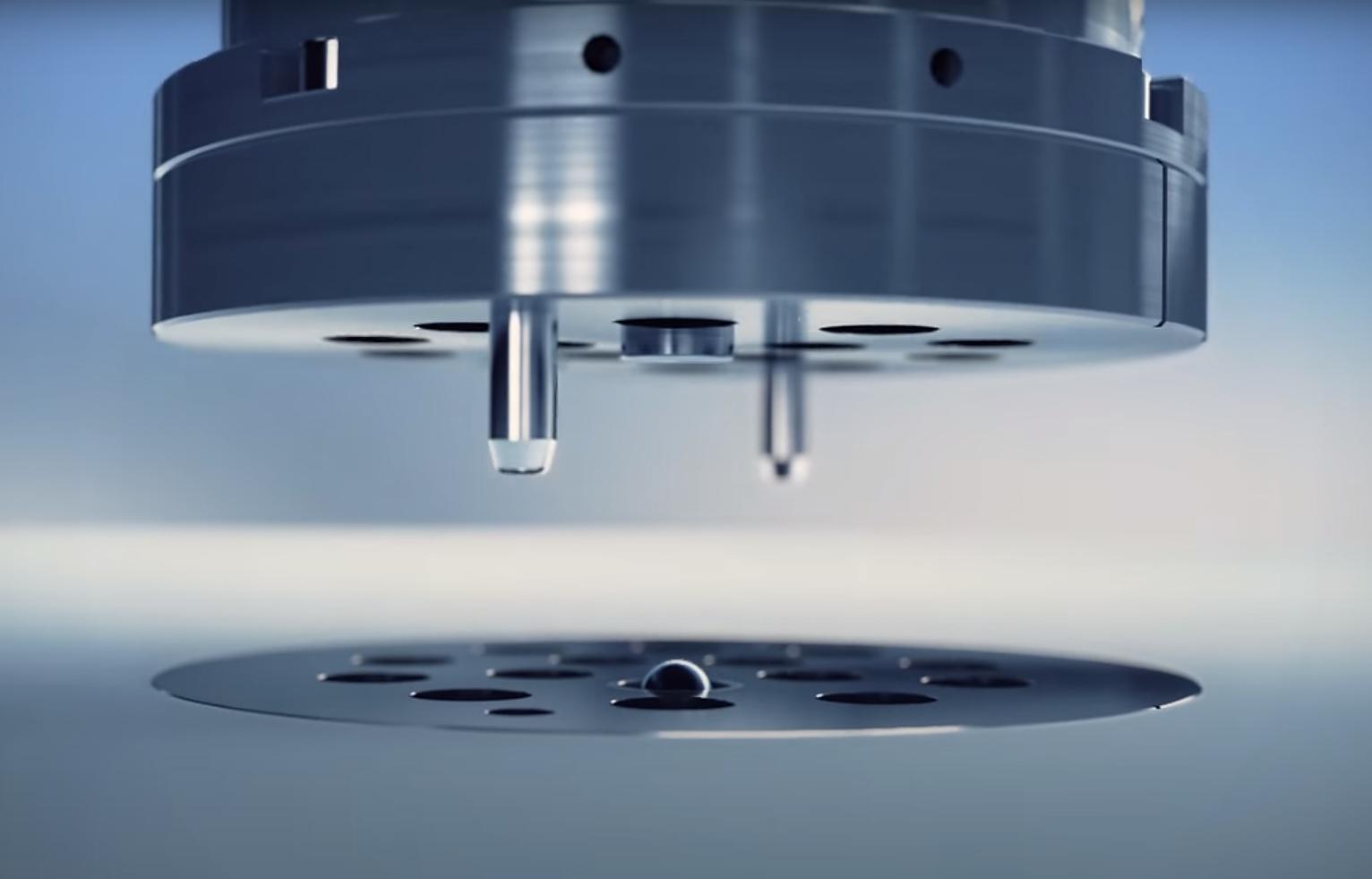

Precision Glass Molding

High-Performance Aspheres Enabling Smart Optical Design

FISBA’s precision glass molding technology enables cost-effective manufacture of aspheric glass lenses in medium to high volumes. From our facilities in St. Gallen, Switzerland, we provide compact, lightweight optical solutions for medical, defense, and industrial applications.

From Design to Production Expertise

Precision molding technology allows glass aspheres to be replicated directly from high-precision molds, reducing the need for post-polishing while maintaining nanometer-level surface accuracy. Compared to spherical lenses, aspheres correct optical aberrations and enable more compact, lighter system designs with fewer components. FISBA integrates the full production chain, from ultra-precision tooling fabrication to metrology, coating, and assembly, under one roof. This vertical integration ensures fast iteration, consistent quality, and full traceability from concept to serial production.

Technical Data

- Irregularities down to < 150nm PV

- Moldable glass types with refractive indexes from 1,5 und 1,9

- Moldable glass types with abbe numbers from 21 bis > 68

Engineering the Process

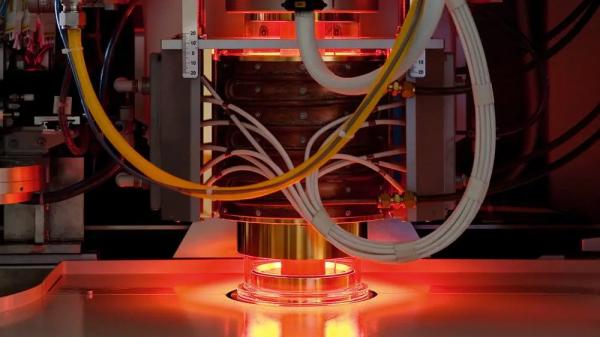

Molded glass aspheres require careful control of preform geometry, heating, and cooling to prevent excessive residual stress and refractive index variations. Our engineers optimize every process parameter - from preform geometry and heating profiles to controlled cooling rates - to prevent unreasonable residual stress and refractive index variation. Through simulation and experience, we compensate for index drop and shrinkage, ensuring optical performance remains within tolerance.

Our In-House Capabilities Include:

- Ultra-Precision Tooling: Diamond-ground molds for complex aspheric geometries

- Controlled-Atmosphere Molding: Cleanroom environments for optical-grade surfaces

- Advanced Metrology: UA3P tactile measurement and interferometric verification

- Centering & Grinding: Non-rotational geometries and micro-optics finishing Optical

- Coating & Assembly: AR coatings, black chromium, and cemented optics integration

Why FISBA for Precision Glass Molding

With decades of precision glass molding experience, FISBA delivers complete, traceable optical solutions from prototype to volume production.

- Proven track record in asphere design and serial manufacturability

- Deep process know-how for thermal management and index compensation

- In-house production for coating, alignment, and quality assurance

- Reliable partner for high-precision optics made in Switzerland